Reading analog gauges with the Nicla Vision

Reading analog gauges with the Nicla Vision

Arduino Team — August 13, 2022

Analog instruments are everywhere and are used to measure pressure, temperature, power levels and much more. Due to the advent of digital sensors, many of them quickly became obsolete, leaving others to require either conversions to digital format or frequent human monitoring. However, the Zalmotek team has come up with a solution that incorporates built-in machine learning and computer vision to read these values autonomously.

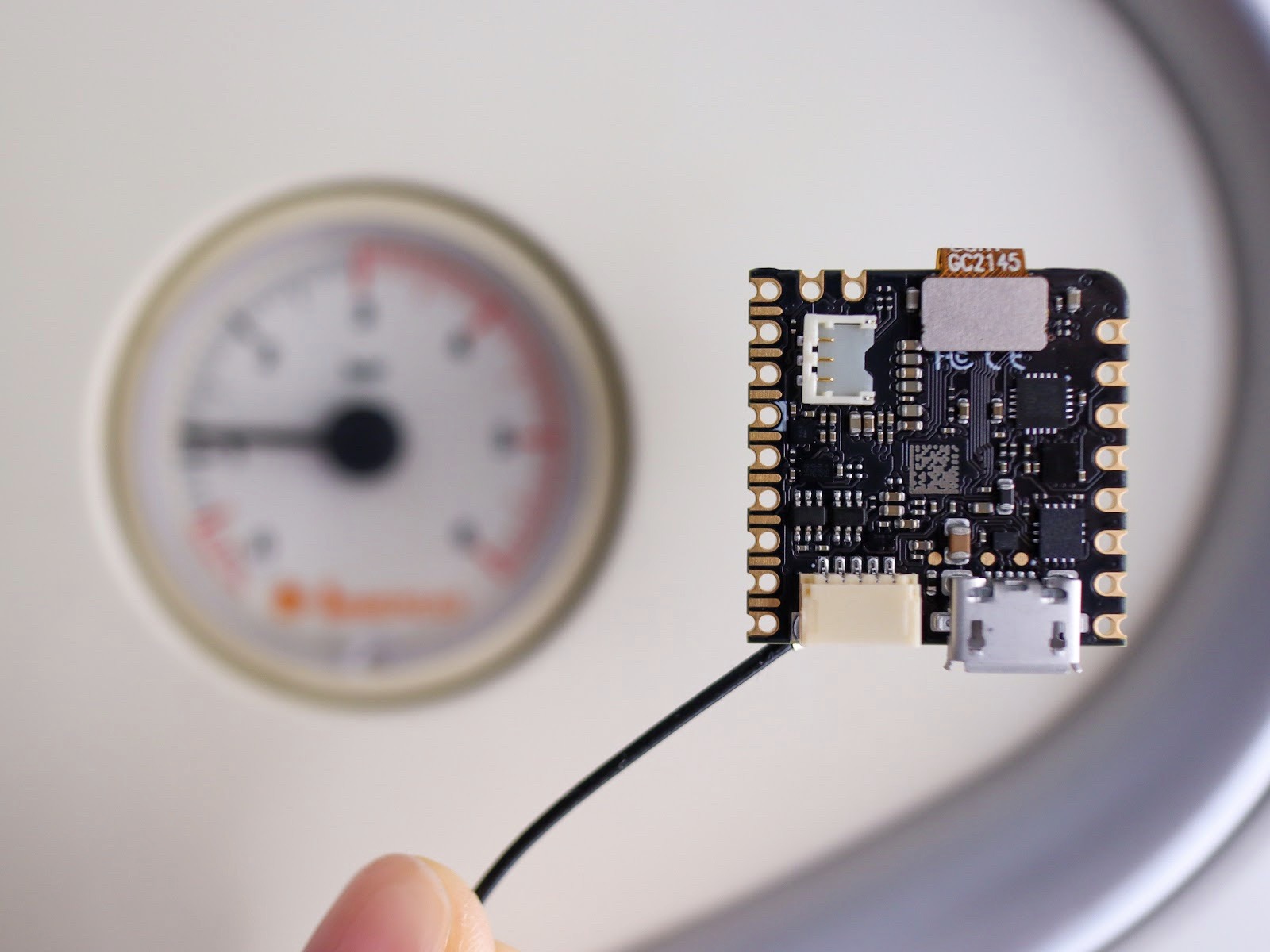

Mounted inside a custom case, their project relies on an Arduino Pro Nicla Vision board, which takes periodic images for further processing and inference. They started by generating a series of synthetic gauge images that have the dial at different positions and labeled them either low, normal, or high. This collection was then imported into Edge Impulse Studio and used to train a machine learning model on the 96x96px samples due to limited memory. Once created, the neural network could successfully determine the state of the gauge about 92% of the time.

The final step of this project was to deploy the firmware to Nicla Vision and set the image size to the aforementioned 96x96px size. By choosing to use this computer vision technique, frequent readings can be performed while minimizing cost and power consumption.

Arduino Team — August 13, 2022

Analog instruments are everywhere and are used to measure pressure, temperature, power levels and much more. Due to the advent of digital sensors, many of them quickly became obsolete, leaving others to require either conversions to digital format or frequent human monitoring. However, the Zalmotek team has come up with a solution that incorporates built-in machine learning and computer vision to read these values autonomously.

Mounted inside a custom case, their project relies on an Arduino Pro Nicla Vision board, which takes periodic images for further processing and inference. They started by generating a series of synthetic gauge images that have the dial at different positions and labeled them either low, normal, or high. This collection was then imported into Edge Impulse Studio and used to train a machine learning model on the 96x96px samples due to limited memory. Once created, the neural network could successfully determine the state of the gauge about 92% of the time.

The final step of this project was to deploy the firmware to Nicla Vision and set the image size to the aforementioned 96x96px size. By choosing to use this computer vision technique, frequent readings can be performed while minimizing cost and power consumption.

What's Your Reaction?