Blaze That Laser Cutter: Upgrade a K40

Digital manufacturing tools can cost hundreds to tens of thousands of dollars. For manufacturers interested in a truly useful tool at a relatively low initial cost with huge upgrade potential, the generic 40W "K40" type CO2 laser platform is hard to beat.

Much more powerful than diode lasers, K40 lasers can cut wood, leather, acrylic, paper and a range of other materials (typically up to about ¼ inch thick, although this varies by material). It will engrave on many other types of materials, although it struggles with metal engraving. While more powerful (and expensive) lasers can surpass these capabilities, the K40 can be vastly improved with end-user upgrades. In almost every case, applying every upgrade available on a K40 still results in a less expensive tool than upgrading to a 50W or 60W laser.

For makers ready to go beyond diode laser solutions, the K40 is a fun and affordable platform ready for modification. Here are my recommendations, based on the improvements I've made to mine.

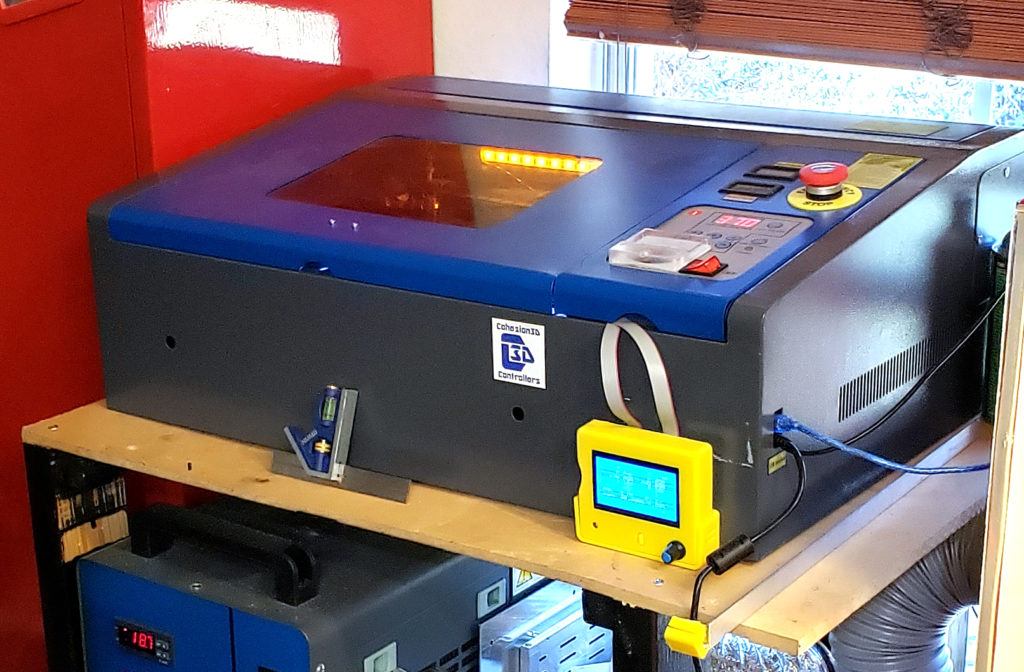

If you want to upgrade a K40, you must start with a K40. I got mine from OMTech, a US-based company that adds value to buying the general K40 model (for a price of course) by checking the quality of build, components, etc. Cheaper, nearly identical units are directly importable, but often have component or construction issues. This unit is absolutely functional right out of the box, but the platform is also a great base for upgrades.

Price: $450, Return on Investment (ROI): 8 Ease of installation (1 = poor, 10 = excellent): 8 Instructions Recommendation: TOTALLY REQUIRED!

Digital manufacturing tools can cost hundreds to tens of thousands of dollars. For manufacturers interested in a truly useful tool at a relatively low initial cost with huge upgrade potential, the generic 40W "K40" type CO2 laser platform is hard to beat.

Much more powerful than diode lasers, K40 lasers can cut wood, leather, acrylic, paper and a range of other materials (typically up to about ¼ inch thick, although this varies by material). It will engrave on many other types of materials, although it struggles with metal engraving. While more powerful (and expensive) lasers can surpass these capabilities, the K40 can be vastly improved with end-user upgrades. In almost every case, applying every upgrade available on a K40 still results in a less expensive tool than upgrading to a 50W or 60W laser.

For makers ready to go beyond diode laser solutions, the K40 is a fun and affordable platform ready for modification. Here are my recommendations, based on the improvements I've made to mine.

If you want to upgrade a K40, you must start with a K40. I got mine from OMTech, a US-based company that adds value to buying the general K40 model (for a price of course) by checking the quality of build, components, etc. Cheaper, nearly identical units are directly importable, but often have component or construction issues. This unit is absolutely functional right out of the box, but the platform is also a great base for upgrades.

Price: $450, Return on Investment (ROI): 8 Ease of installation (1 = poor, 10 = excellent): 8 Instructions Recommendation: TOTALLY REQUIRED!

What's Your Reaction?