This handy machine automatically cuts plastic gears

This handy machine automatically cuts plastic gears

Arduino Team — October 13, 2022

Many mechanisms require gears, but the good news is that plastic gears are very inexpensive. The bad news is that you have to buy a lot of them at once, which means you need to know what gears you need in advance. Being able to make gears on demand would be very handy, but most 3D printers don't have the tolerance to do this well and CNC setups are expensive. But by following Mr Innovative's recent video, you can build your own affordable machine that automatically cuts gears.

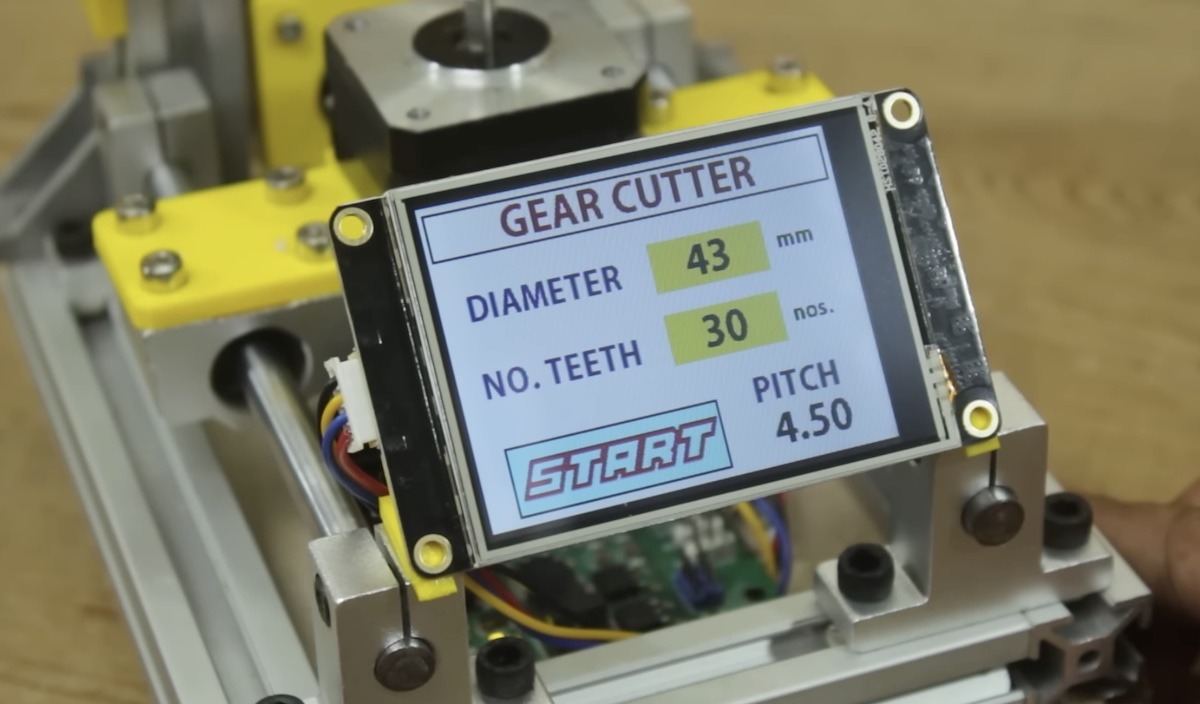

It might be able to handle very soft metals, but it's really meant for cutting nylon and other plastics. Users can set the diameter and number of teeth, which together dictate the pitch. However, they cannot change the cutting profile of the teeth without swapping the blade. They set the parameters on a Nextion LCD touchscreen, and then the machine takes care of the rest. It rotates the gear according to the calculated pitch, then moves the gear in the circular cutting blade according to the defined diameter.

An Arduino Nano board interfaces with the Nextion LCD and controls the two stepper motors via drivers on a custom shield, as well as the large DC motor that spins the blade. The gear blank mounts directly to one stepper motor via a coupler, while the second stepper motor controls linear motion via a lead screw. The frame is a combination of aluminum extrusion and 3D printed parts, with bearing blocks for linear motion.

A manufacturer could buy a lot of gears with the money it takes to build this machine, but the ability to cut custom gears to exact specifications whenever needed would be very handy.

Arduino Team — October 13, 2022

Many mechanisms require gears, but the good news is that plastic gears are very inexpensive. The bad news is that you have to buy a lot of them at once, which means you need to know what gears you need in advance. Being able to make gears on demand would be very handy, but most 3D printers don't have the tolerance to do this well and CNC setups are expensive. But by following Mr Innovative's recent video, you can build your own affordable machine that automatically cuts gears.

It might be able to handle very soft metals, but it's really meant for cutting nylon and other plastics. Users can set the diameter and number of teeth, which together dictate the pitch. However, they cannot change the cutting profile of the teeth without swapping the blade. They set the parameters on a Nextion LCD touchscreen, and then the machine takes care of the rest. It rotates the gear according to the calculated pitch, then moves the gear in the circular cutting blade according to the defined diameter.

An Arduino Nano board interfaces with the Nextion LCD and controls the two stepper motors via drivers on a custom shield, as well as the large DC motor that spins the blade. The gear blank mounts directly to one stepper motor via a coupler, while the second stepper motor controls linear motion via a lead screw. The frame is a combination of aluminum extrusion and 3D printed parts, with bearing blocks for linear motion.

A manufacturer could buy a lot of gears with the money it takes to build this machine, but the ability to cut custom gears to exact specifications whenever needed would be very handy.

What's Your Reaction?