This large format laser cutter was built from the ground up for just $700

This large format laser cutter was built from the ground up for just $700

Arduino Team — June 30, 2022

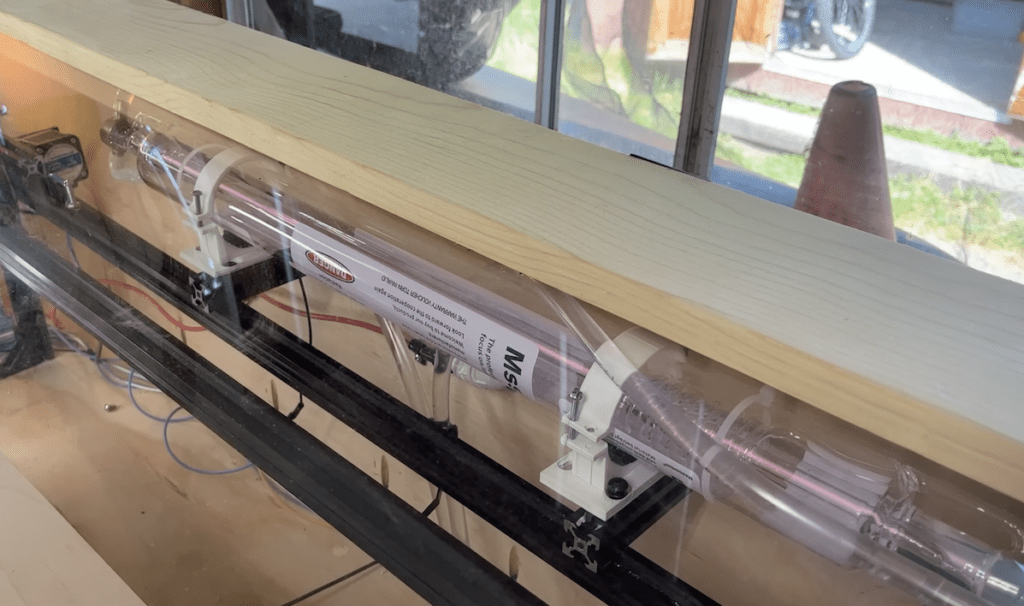

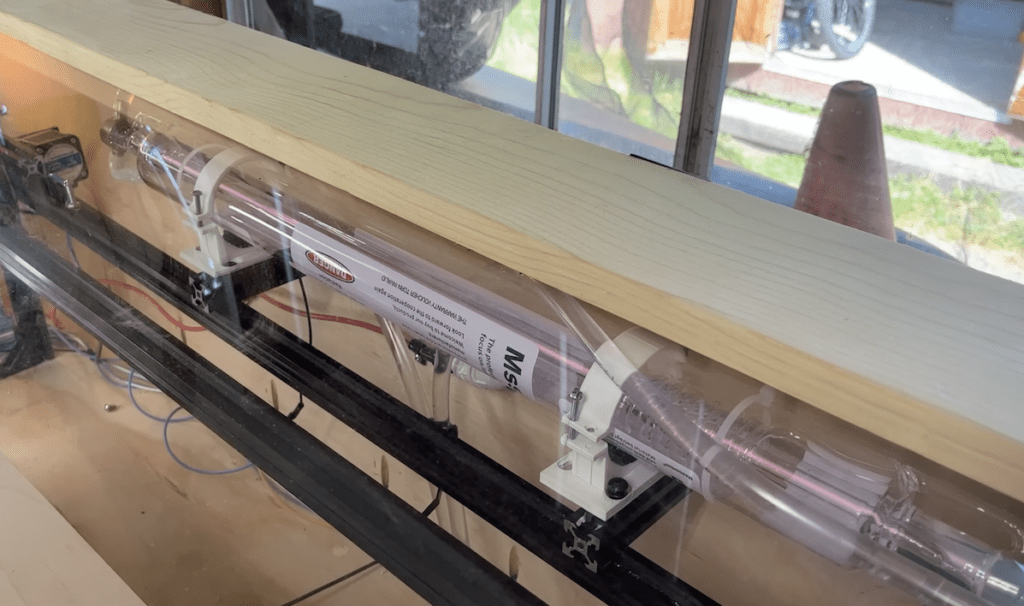

When stuck between a cheaper but small laser cutter and splurging on a much larger cutter, Owen Schafer instead decided to build one himself. The project began with Schafer obtaining a 40W CO2 laser, which differs from a diode laser in that it uses gas heated to 16,000 volts to produce a very powerful beam of light. This had the added side effect of requiring a water cooling system since the tube tends to generate large amounts of heat.

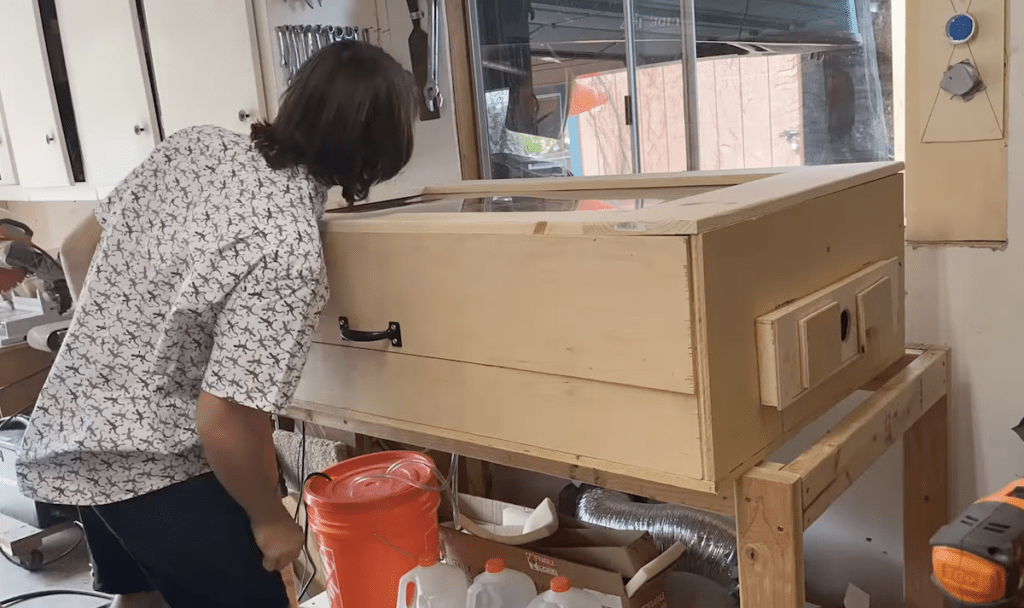

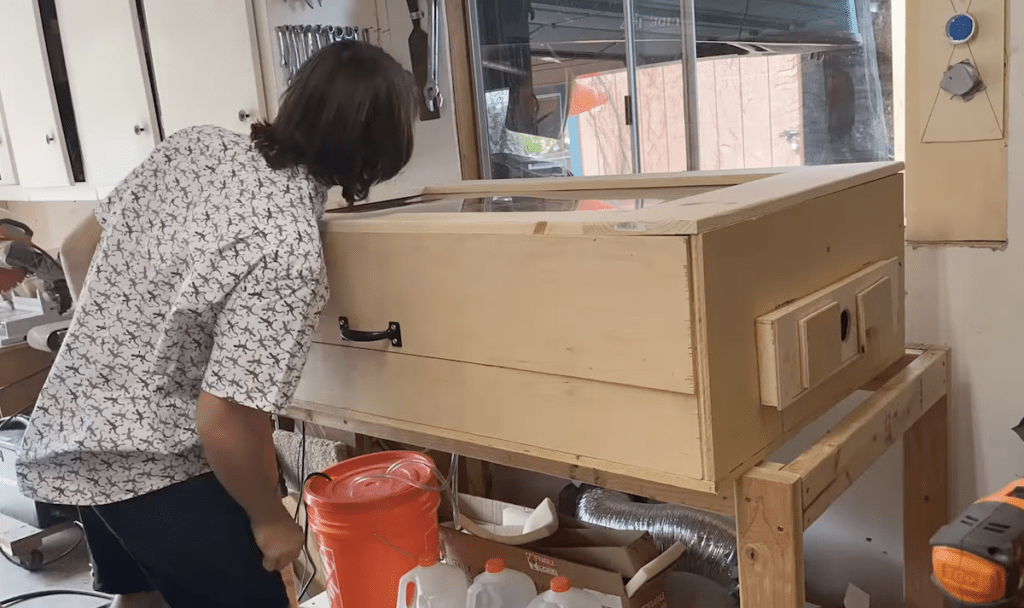

Once the necessary laser and reflectors were found, Schafer purchased aluminum extrusions and attached them with corner connectors. The head moves using a gantry, in which the X axis slides along the Y axis, and both are driven by NEMA17 stepper motors and a timing belt. For added security, he created a basic plywood enclosure in case something went wrong inside.

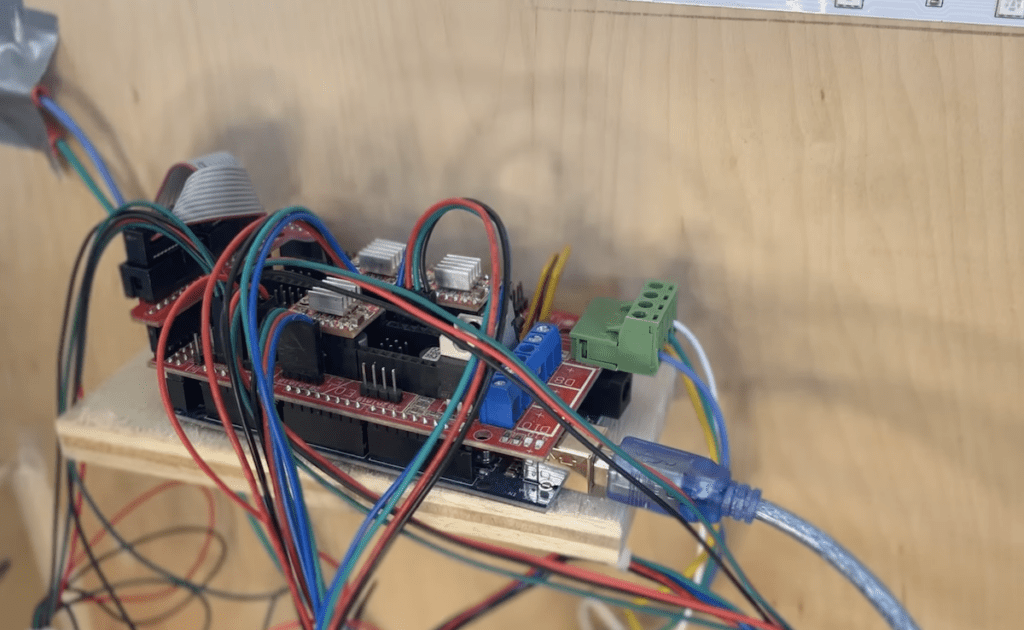

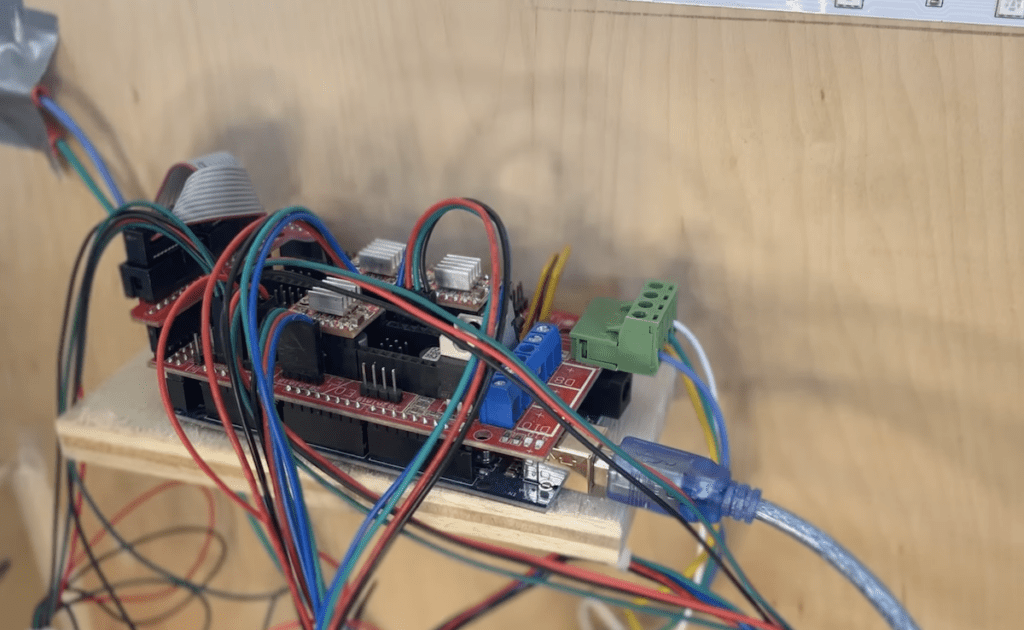

Each stepper motor is driven by an A4988 driver module, and all are controlled by an Arduino Mega 2560 loaded with the Marlin-based Marlaser laser cutter firmware. It even included some LED strips in the enclosure that aid visibility and a simple ventilation system for fume extraction.

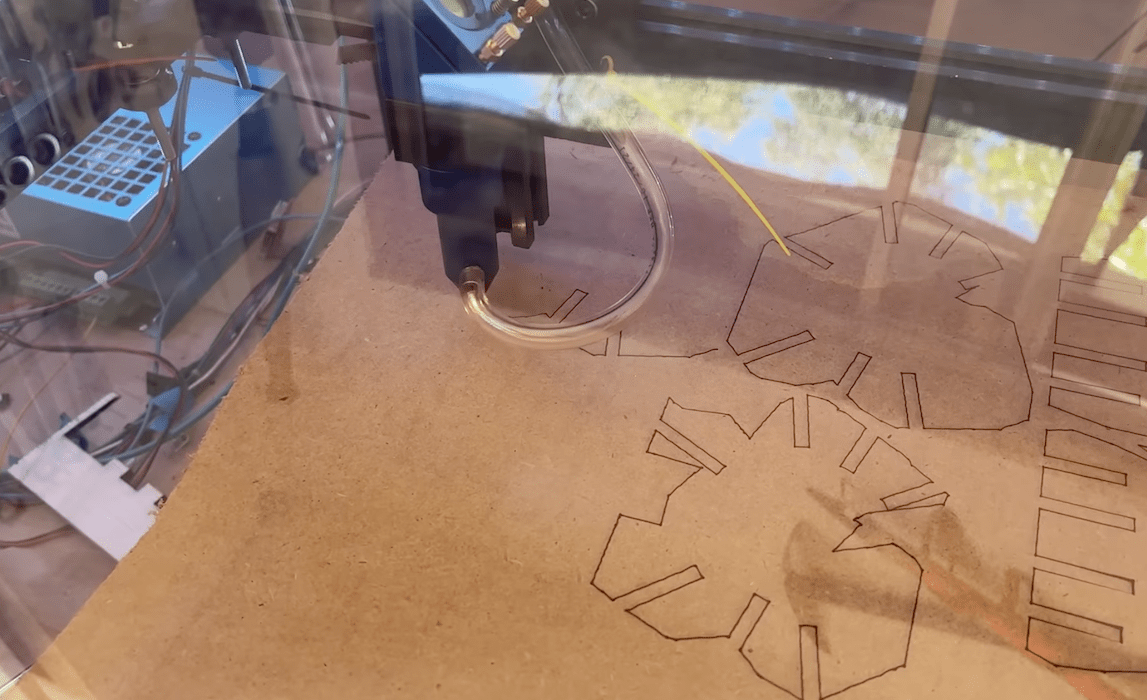

After generating toolpaths using Inkscape, the laser was finally able to cut almost anything in materials ranging from plastic to plywood. You can learn more about how Schafer brought this inexpensive laser cutter to life in the video below!

Arduino Team — June 30, 2022

When stuck between a cheaper but small laser cutter and splurging on a much larger cutter, Owen Schafer instead decided to build one himself. The project began with Schafer obtaining a 40W CO2 laser, which differs from a diode laser in that it uses gas heated to 16,000 volts to produce a very powerful beam of light. This had the added side effect of requiring a water cooling system since the tube tends to generate large amounts of heat.

Once the necessary laser and reflectors were found, Schafer purchased aluminum extrusions and attached them with corner connectors. The head moves using a gantry, in which the X axis slides along the Y axis, and both are driven by NEMA17 stepper motors and a timing belt. For added security, he created a basic plywood enclosure in case something went wrong inside.

Each stepper motor is driven by an A4988 driver module, and all are controlled by an Arduino Mega 2560 loaded with the Marlin-based Marlaser laser cutter firmware. It even included some LED strips in the enclosure that aid visibility and a simple ventilation system for fume extraction.

After generating toolpaths using Inkscape, the laser was finally able to cut almost anything in materials ranging from plastic to plywood. You can learn more about how Schafer brought this inexpensive laser cutter to life in the video below!

What's Your Reaction?