Improve laser engraving speeds with an Arduino-controlled turntable

Improve laser engraving speeds with A Controlled by Arduino rotating plate

Arduino Team — June the 15th, 2024

Engraving items with A laser based system has House East surprisingly practical For unique rooms, but What arrived When THE production volume needs has increase? For element14 Gifts host Clem Mayer, This generally supposed preparing a lot uniform pieces of engraving action, opening THE the laser pregnant, placement down THE material, And SO Finally running THE machine. In TO DO SO, THE process could introduce Errors And was simply ineffective, leader Mayer has think of A path has automate things instead.

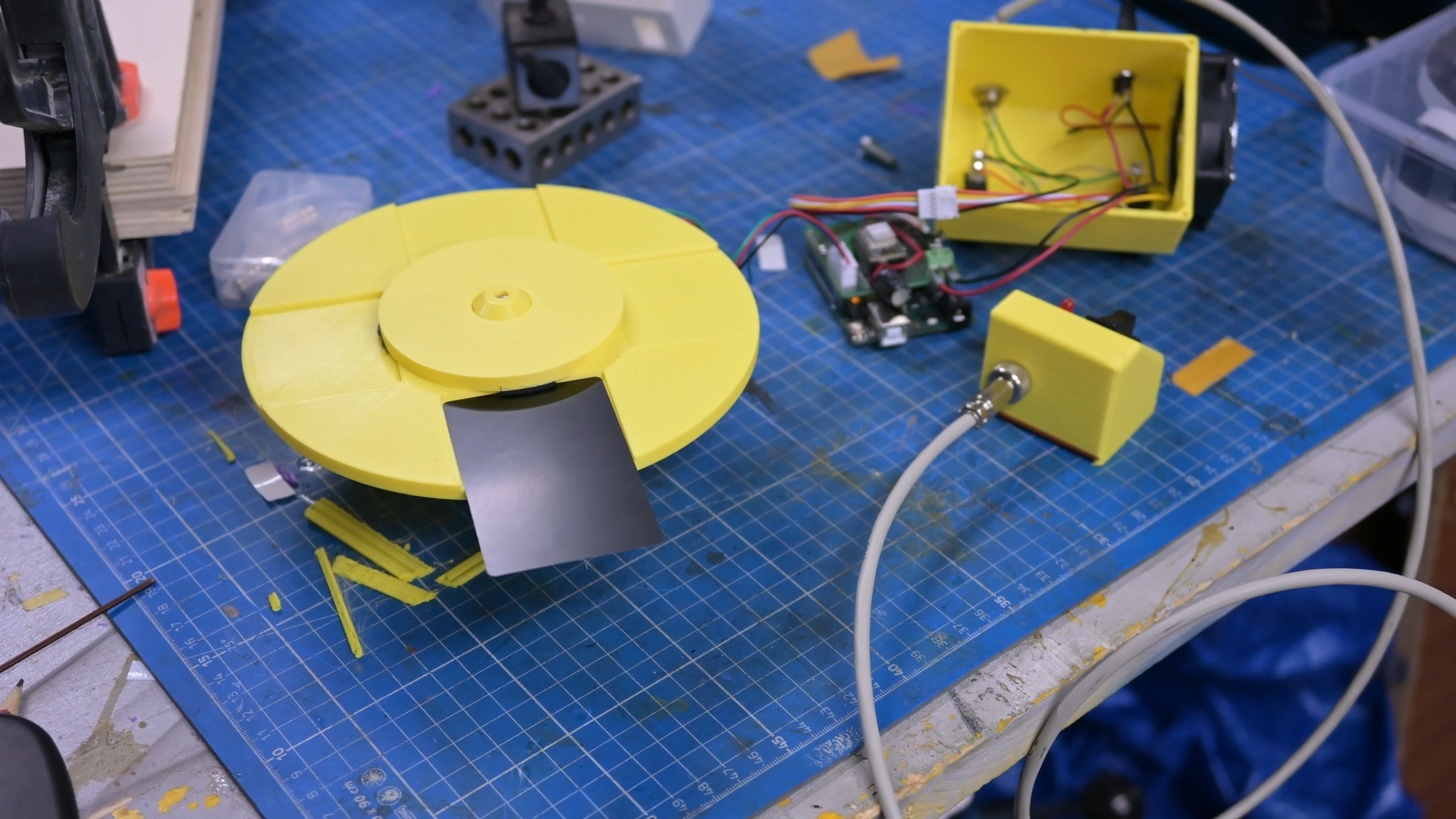

THE limiting postman was Above all about how long he took has change THE material, SO Mayer obtained has work design A carousel shaped device that could House up has four leaves of action And turn each A In place After THE previous A had finished. A step by step engine led by A Trinamic TMC2100 was responsible For moving THE drum while A Arduino UN Rev3 received contributions Since external switches And SO sent legumes has THE engine driver accordingly.

Once put In THE laser cutter pregnant, Mayer quickly discovered that her vertical drum design was Also big And interfered with THE tool head. This need exchange THE orientation has A flat disk Or material could be positioned around A spinning turn painting. THE original on springs pliers were Also exchange For A magnetic system that East strong Again easily removable.

HAS see more about This project, You can watch Mayer build save video below!

Arduino Team — June the 15th, 2024

Engraving items with A laser based system has House East surprisingly practical For unique rooms, but What arrived When THE production volume needs has increase? For element14 Gifts host Clem Mayer, This generally supposed preparing a lot uniform pieces of engraving action, opening THE the laser pregnant, placement down THE material, And SO Finally running THE machine. In TO DO SO, THE process could introduce Errors And was simply ineffective, leader Mayer has think of A path has automate things instead.

THE limiting postman was Above all about how long he took has change THE material, SO Mayer obtained has work design A carousel shaped device that could House up has four leaves of action And turn each A In place After THE previous A had finished. A step by step engine led by A Trinamic TMC2100 was responsible For moving THE drum while A Arduino UN Rev3 received contributions Since external switches And SO sent legumes has THE engine driver accordingly.

Once put In THE laser cutter pregnant, Mayer quickly discovered that her vertical drum design was Also big And interfered with THE tool head. This need exchange THE orientation has A flat disk Or material could be positioned around A spinning turn painting. THE original on springs pliers were Also exchange For A magnetic system that East strong Again easily removable.

HAS see more about This project, You can watch Mayer build save video below!

What's Your Reaction?

![Three of ID's top PR executives quit ad firm Powerhouse [EXCLUSIVE]](https://variety.com/wp-content/uploads/2023/02/ID-PR-Logo.jpg?#)