Force monitoring of a 20 ton hydraulic press

Force monitoring of a 20 ton hydraulic press

Arduino Team — August 29, 2022

Materials testing often boils down to breaking objects and measuring the force required to do so. The way something breaks is the result of different strength properties. There are many types of strength, but mechanical engineers are most concerned with tensile, compressive, shear, and torsion strength. The easiest way to test compressive strength is to crush something with a very powerful press. Clem Mayer from Element14 Presents bought a 20 ton hydraulic press for this purpose and used an Arduino to measure its force.

Even if you have no in-store experience, you've probably seen a hydraulic press in action in one of those YouTube videos where they press household objects until they explode in a fun way. This particular press can exert up to 20 tons of force, which is about as heavy as three elephants. The actual pressure depends on the surface to which the force is applied. To calculate the pressure at the time of failure, Mayer needs the contact area (easy to measure in advance) and the current force applied by the press. He collected the pressure data using an Arduino Leonardo and a load cell.

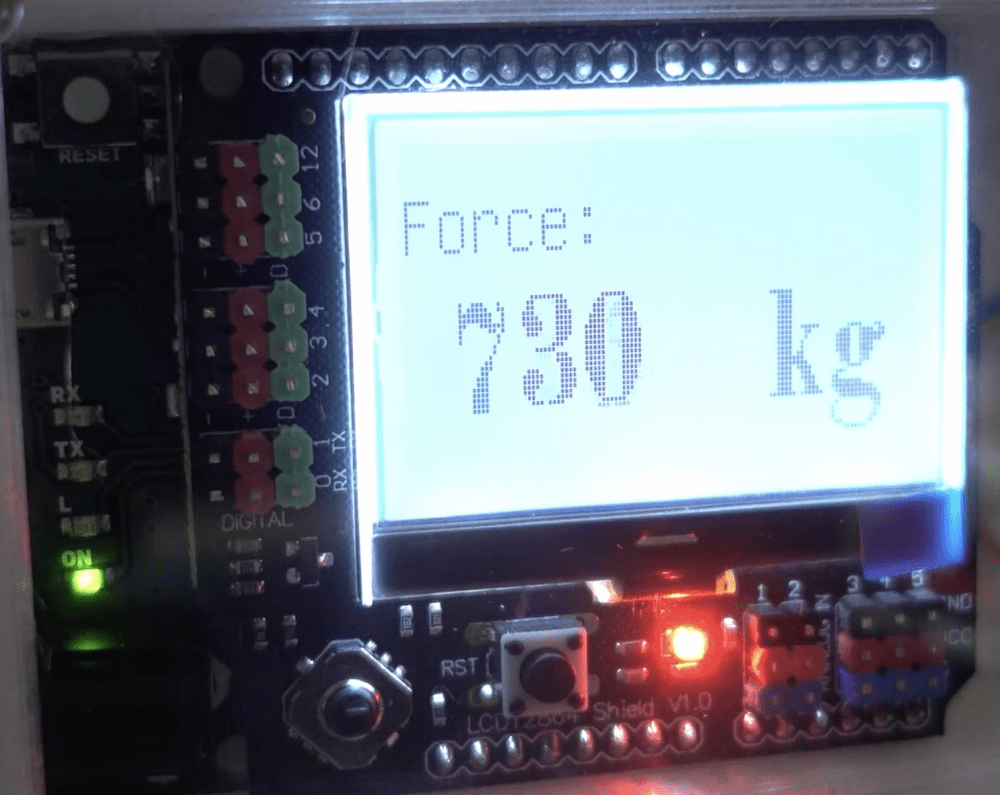

A load cell is a type of force sensor consisting of four strain gauges connected through a Wheatstone bridge. Strain gauges produce resistance that varies with strain, which correlates with force. Normally they are inaccurate and require tedious calibration, but the Wheatstone Bridge uses four of them and some clever calculations to easily produce an accurate measurement. The output signal is weak, therefore an HX711 amplifier is required to make the signal usable. The Arduino measures the output of the HX711 using an ADC (analog to digital converter) which connects via I2C. It then displays the maximum reading on a small LCD screen. This reading should peak just before the object under test breaks, which tells Mayer how strong the material under test is.

Arduino Team — August 29, 2022

Materials testing often boils down to breaking objects and measuring the force required to do so. The way something breaks is the result of different strength properties. There are many types of strength, but mechanical engineers are most concerned with tensile, compressive, shear, and torsion strength. The easiest way to test compressive strength is to crush something with a very powerful press. Clem Mayer from Element14 Presents bought a 20 ton hydraulic press for this purpose and used an Arduino to measure its force.

Even if you have no in-store experience, you've probably seen a hydraulic press in action in one of those YouTube videos where they press household objects until they explode in a fun way. This particular press can exert up to 20 tons of force, which is about as heavy as three elephants. The actual pressure depends on the surface to which the force is applied. To calculate the pressure at the time of failure, Mayer needs the contact area (easy to measure in advance) and the current force applied by the press. He collected the pressure data using an Arduino Leonardo and a load cell.

A load cell is a type of force sensor consisting of four strain gauges connected through a Wheatstone bridge. Strain gauges produce resistance that varies with strain, which correlates with force. Normally they are inaccurate and require tedious calibration, but the Wheatstone Bridge uses four of them and some clever calculations to easily produce an accurate measurement. The output signal is weak, therefore an HX711 amplifier is required to make the signal usable. The Arduino measures the output of the HX711 using an ADC (analog to digital converter) which connects via I2C. It then displays the maximum reading on a small LCD screen. This reading should peak just before the object under test breaks, which tells Mayer how strong the material under test is.

What's Your Reaction?

![Three of ID's top PR executives quit ad firm Powerhouse [EXCLUSIVE]](https://variety.com/wp-content/uploads/2023/02/ID-PR-Logo.jpg?#)