The automated winder has an automatic reversing screw

The world of mechanical engineering is full of interesting and ingenious mechanisms. The Geneva Reader, for example, translates rotary motion into intermittent ticking - perfect for a wristwatch or clock. With an intelligent mechanism, the need for complicated control electronics can be reduced. This was the case with the self-reversing screw that moves the guide on Mr Innovative's automated winder.

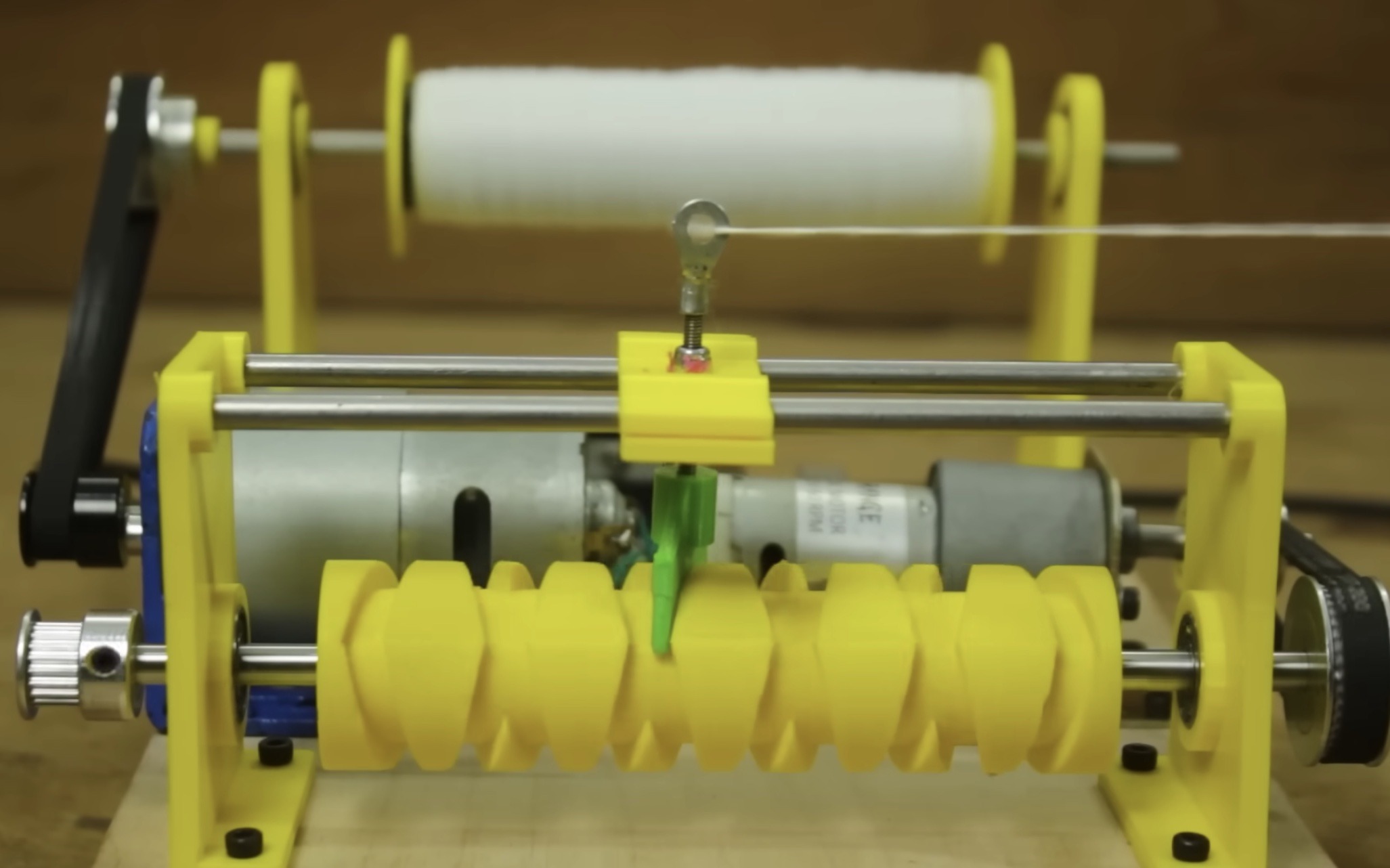

This is a winding machine for loading string, thread, thread or thread onto a spool, similar to the bobbin winder you find on a sewing machine. To ensure an even and tight winding, the machine must guide the yarn back and forth along the length of the bobbin. Many of us would jump straight to electronic control to guide wire, perhaps involving a stepper motor and limit switches. But as Mr. Innovative shows, it doesn't have to be. All it needed was the right mechanism: a self-reversing screw.

Like most of the mechanical parts of this machine, the screw was 3D printed. It has two-way threads, so it can move the guide either way. At the ends there are grooves that swing the guide over the other wires so that it changes direction. This simple mechanism is driven by a single geared DC motor.

A second DC motor spins the spool, so it wraps the wire around itself. An Arduino Nano board controls both motors via Mr Innovative's custom control board. The sketch is very simple and just tells the motors to run at a set speed as long as they have power.

Besides being useful, this machine illustrates the importance of a well-thought-out mechanical design.

The world of mechanical engineering is full of interesting and ingenious mechanisms. The Geneva Reader, for example, translates rotary motion into intermittent ticking - perfect for a wristwatch or clock. With an intelligent mechanism, the need for complicated control electronics can be reduced. This was the case with the self-reversing screw that moves the guide on Mr Innovative's automated winder.

This is a winding machine for loading string, thread, thread or thread onto a spool, similar to the bobbin winder you find on a sewing machine. To ensure an even and tight winding, the machine must guide the yarn back and forth along the length of the bobbin. Many of us would jump straight to electronic control to guide wire, perhaps involving a stepper motor and limit switches. But as Mr. Innovative shows, it doesn't have to be. All it needed was the right mechanism: a self-reversing screw.

Like most of the mechanical parts of this machine, the screw was 3D printed. It has two-way threads, so it can move the guide either way. At the ends there are grooves that swing the guide over the other wires so that it changes direction. This simple mechanism is driven by a single geared DC motor.

A second DC motor spins the spool, so it wraps the wire around itself. An Arduino Nano board controls both motors via Mr Innovative's custom control board. The sketch is very simple and just tells the motors to run at a set speed as long as they have power.

Besides being useful, this machine illustrates the importance of a well-thought-out mechanical design.

What's Your Reaction?